Prototypes

Prototypes

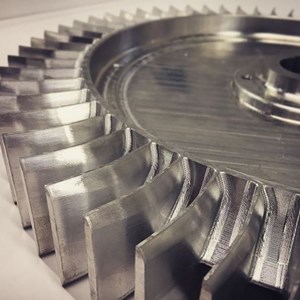

Prototype production through machining, casting or 3D printing. There has been a greater focus on one of the company’s business areas – The ability to offer prototypes at the design stage with the capacity for mass production is unique.

Evaluate a future product or improve an existing one. We are more than a supplier of products. We contribute experience and knowledge when a project is born. We provide valuable advice about production methods, materials and alloys. The most cost-effective manufacturing method is matched up with the best logistics solution and to visualise the options, we help by providing prototypes.

Production method -> Prototype production -> Mass production -> Warehousing

We can cast or use machining to produce one or more samples of a part that will be mass produced. This gives you the opportunity to evaluate the design, construction and strength. Prototypes that will subsequently be cast or forged are machined in the same material/alloy as the intended finished product. Surface treatments/coatings and painting are also undertaken.

PRODUKTIONSTEKNIKER

Prototypes

Prototypes

Evaluate a future product or improve an existing one. Development through machining or 3D printing.

METAL INJECTION MOULDING – MIM

METAL INJECTION MOULDING – MIM

Metal injection moulding, MIM, is very similar to the injection moulding of plastic parts. Extremely complicated shapes can be manufactured with high precision.

Powder Metallurgy (PM)

Powder Metallurgy (PM)

A production technology in which a powder is compressed under high pressure in a closed tool to create the shape of the part.

Investment casting (lost wax)

Investment casting (lost wax)

By using what is known as the lost wax process, products can be cast with very high precision.

PRESSURE DIE CASTING

PRESSURE DIE CASTING

During pressure die casting molten metal is forced into a mould under pressure. A high degree of dimensional accuracy can be attained, which often results in less machining.

SAND CASTING

SAND CASTING

Sand casting is a cost-effective process for small and medium-sized production runs where the precision and surface requirements are not crucial factors.

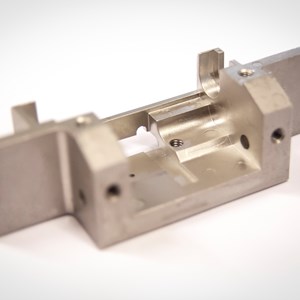

MACHINING

MACHINING

Everything from simple to complicated machining. Cost-effective and where precision and demanding tolerance and surface requirements are specified.

FORGING AND HOT FORGING

FORGING AND HOT FORGING

We often recommend forging or hot forging when the requirements for strength are high. When the conditions are right, it is possible to save money by switching from machining to forging/hot forging.

Assembly

Assembly

Pre-assembled parts with integral components of varying kinds and materials. An all-in package at a fixed cost.